A dry ridge system is where ridge and hip tiles are fitted to the roof with screws, clamps, and waterproof fixings instead of mortar, sand and cement. Ridge and hip tiles run across the peak of the roof, providing the perfect clean finish to a roof. So, it’s essential that they are installed securely. And, for a long time, roofers have used the traditional sand and cement mortar method to fix ridge and hip tiles to roofs. However, dry ridge systems have become popular in recent years as an alternative method of getting the job done.

But is a dry ridge system any good?

The simple answer is – yes, dry ridge fixing is an excellent solution.

Read on to find out everything about dry ridge systems, their costs and benefits, and the ins and outs of the dry ridge installation process.

Table of contents:

- What is a dry ridge system?

- Dry ridge system cost

- How to install a dry ridge system

- The benefits of a dry ridge system

What is a dry ridge system?

A dry ridge system simply involves fixing ridge and hip tiles to a roof without sand or cement mortar. Instead, you use screws and clamps, which fix each ridge tile to the roof. Then fit waterproof unions beneath the screws to divert water away from the join.

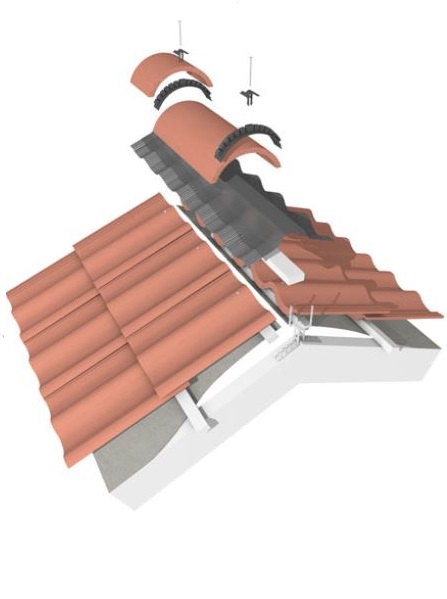

One of the most popular forms of dry ridge systems is the roll-out dry ridge system. The ridge roll is laid out along the ridge before the ridge tiles are installed, to provide a surface on which to connect the ridge tiles.

The roll-out ridge system provides ventilation through the roll of the membrane, whilst also creating a waterproof and weatherproof roof ridge.

Dry ridge system vs mortar

Unlike a contemporary dry ridge roof system, the more traditional sand and cement or mortar method has a number of issues, such as:

- Being time-consuming

- Mortar can crack and fall out over time

- Temperature fluctuations and changes in weather can make mortar brittle

- This sort of wear and tear can leave the roof ridge unstable and exposed to elements

What’s more, mortar-fixed ridge tiles require regular maintenance to prevent them from disconnecting and falling off.

Finally, British Standards, particularly BS 5534:2014+A2:2018 and BS 8216:2018, suggest that the traditional mortar method of fixing tiles onto roofs should only be used where absolutely necessary. This includes period or heritage properties, and for simple repairs.

Dry ridge system cost

If you’re planning on buying a dry ridge system and having it installed by professionals, you should be prepared to fork out anywhere between £50 and £60 per metre.

For a typical semi-detached house, the total would amount to around £275 for a standard dry ridge system, which normally requires around 5 metres of hips.

On the other hand, a dry hip ridge system might set you back by around £770, as it requires as much as 14 metres of hips. That being said, you’re only likely to need one of those if your roof has at least three faces and one or more has a triangular shape.

As with everything else, the price of installation varies considerably across the UK. The price of installation is what really inflates the overall figure, since the kits themselves are quite affordable.

At this point, you’re probably wondering:

How do you fit a dry verge ridge system by yourself?

That’s precisely what we’re going to look at next.

How to fit a dry ridge system

Depending on the dry ridge system you choose, the installation process may vary slightly. We always recommend following the manufacturer’s installation instructions.

Step one: Lay the roofing underlay as normal, and batten the roof up to the top course of roofing battens.

Step two: Adjust the brackets to get them to the appropriate height (this depends on your roof pitch and the size of the tiles). Fix a batten support bracket to the apex of each rafter with stainless steel ring shank nails.

Step three: Lay a timber batten between the support brackets, and then bend the upstands over the batten and fix it in place.

Step four: Lay and fix the roofing tiles in place on each side as per the manufacturer’s recommendations.

Step four: Lay and fix the roofing tiles in place on each side as per the manufacturer’s recommendations.

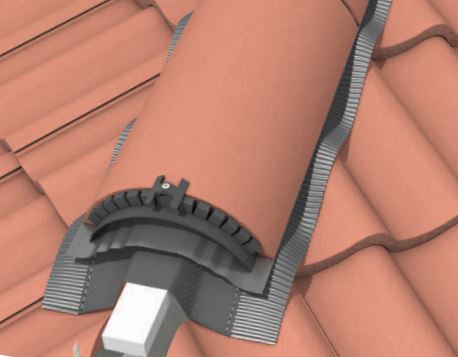

Step five: When the top course tiles are dry, roll the vent roll along the roof ridge. Tack the roll at intervals using staples or roof felt nails. Then remove the backing of the sealing strip, and push the sealing strips down to follow the contours of the roofing tiles.

Step six: Lay the ridge tiles along the ridge, inserting a ridge union in each gap between the tiles. Then screw the clamping plate over the ridge tile and into the batten.

Step seven: Don’t forget to use an end cap or a block-end ridge at the end of the roof ridge.

The benefits of a dry ridge system

Dry ridge systems bring a number of benefits to your roofing project.

Installation

Firstly, the installation process is relatively quick and simple, which can result in big savings in labour and time costs.

Low maintenance

Secondly, once installed, a dry ridge system requires very little maintenance. Traditional mortar-based ridge systems need regular maintenance to replace degraded mortar.

Weatherproof

The sturdiness of the dry ridge system is another of its major draws. During bad weather and strong winds, you can be confident that your ridge tiles will not blow off and cause damage to your roof or anything below. Additionally, the system is waterproof, preventing water ingress into roof spaces, which can occur on damaged mortar-based ridge tile applications.

Flexibility

Dry ridge systems also provide your roof with a level of flexibility that is not achievable with mortar-based ridge systems. Roofs naturally experience some movement, whether it is from vibrations of nearby transport and machinery, or through thermal expansion and contraction. This was one of the causes of cracks appearing in mortar in the traditional ridge systems, but the dry verge system is resistant to this kind of damage.

Ventilation

Another feature of dry ridge systems is that they can provide a level of ventilation that traditional ridge tiles can’t. The roll-out ridge can allow moisture to move out of the roof void, which helps to prevent the build-up of condensation. This may lead to rot and other issues that can lead to structural damage.

Ready to make the move to a dry ridge system? Here at Roofing Superstore, we have a range of different dry ridge systems and dry ridge kit components available, including products from Manthorpe, Cromar, Klober, Marley and Redland among other reputable brands.

If you have any questions or queries, give our team a call on 01752 692 760 and they will be more than happy to help.